Introduction

In today’s fiercely competitive market, manufacturers leveraging advanced 5-axis CNC machining to produce complex components frequently face a critical challenge: budget overruns. The initial machining quote often represents just a fraction of the total cost; hidden expenses from material waste, error-prone multiple setups, and energy consumption can significantly erode project profitability. The root cause lies in traditional, static cost models that focus narrowly on machine hourly rates, overlooking the dynamic impact of design, process planning, and sustainability practices on the total cost of ownership. Many companies fail to maximize the capabilities of 5-axis technology, paying a premium for advanced capabilities without realizing the corresponding value.

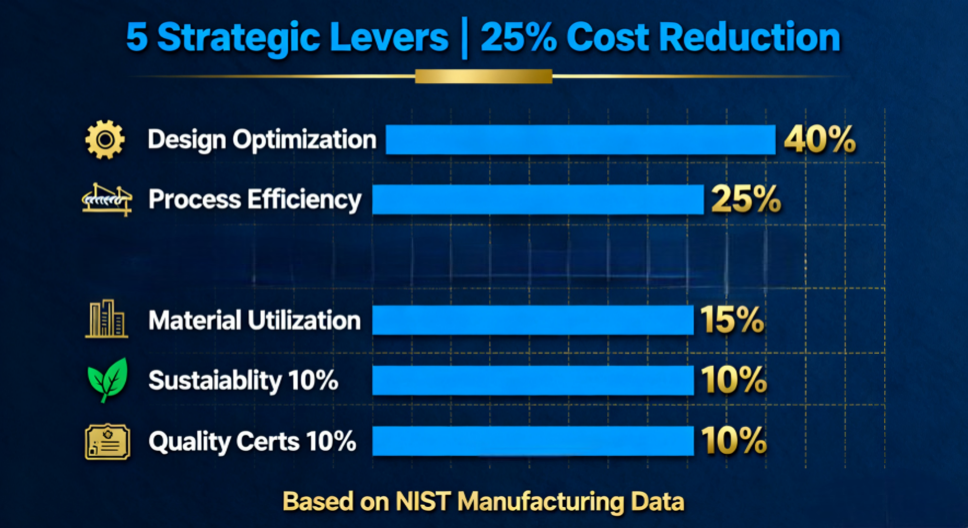

This article unveils five frequently overlooked strategic levers that systematically optimize the entire manufacturing workflow from design to delivery. By focusing on these areas, businesses can not only calculate 5-axis CNC cost with precision but also achieve cost savings of up to 25% while enhancing product quality and environmental performance. The following sections will dissect these five key dimensions to provide a comprehensive framework for cost optimization.

What Are the True Drivers Behind a 5-Axis CNC Machining Quote?

Moving beyond the simplistic “machine time x rate” model is the first step toward genuine cost control. A sophisticated quote reflects a complexity coefficient, material utilization efficiency, and the upfront programming and setup costs.

1. Deconstructing the Quote: More Than Just Machine Time

The base machine rate is a starting point, but the true drivers of cost are often found in the part’s geometry. Complex designs requiring intricate tool paths, deep cavities, or undercuts demand more sophisticated programming, slower feed rates, and specialized tooling, all contributing to a higher 5-axis machining quote.

2. The Power of Value Engineering and DFM

Investing in Design for Manufacturability (DFM) analysis during the quoting phase is a powerful form of value engineering. A manufacturer experienced in 5-axis CNC machining services can identify potential cost traps—like features that necessitate unnecessary tool changes or unstable fixturing—before production begins. This collaborative approach, grounded in rigorous processes often certified by ISO 9001 quality management standards, ensures pricing is both accurate and consistent, forming a reliable foundation for project budgeting.

3. Material Utilization: A Hidden Cost Center

The efficiency with which a part is nested from a raw block of material directly impacts cost. Advanced software can optimize nesting to minimize scrap, but part orientation and geometry play a huge role. A design that allows for efficient material use significantly reduces waste and associated expenses.

How Can Design Optimization Directly Slash Machining Expenses?

Design optimization is arguably the most powerful lever for cost reduction. A design engineered for the unique advantages of 5-axis machining can dramatically streamline production.

- Leveraging Single-Setup Machining: The primary advantage of 5-axis technology is the ability to machine complex features in a single setup. A design that consolidates multiple components or eliminates the need for manual repositioning avoids the cumulative errors and time associated with multiple fixturing. This directly slashes labor, quality control costs, and the risk of scrap, making complex part fabrication far more efficient.

- Simplifying Geometry for Smart Production: NIntelligent design choices have a profound impact. Avoiding deep, narrow cavities that require long, fragile tools, specifying appropriate corner radii to match standard tooling, and designing for accessible tool paths all contribute to reduced machining time and tool wear. These smart production solutions are key to reduce 5-axis machining cost without compromising function.

- The Critical Role of DFM Guidance: Successfully executing this strategy requires early collaboration. A comprehensive DFM guide, such as the insights found in a detailed resource on 5-axis CNC machining costs, empowers engineers to make informed decisions during the design phase, avoiding common pitfalls and locking in significant savings before a single part is cut.

Is Choosing the Right Material and Finish a Cost-Saving Opportunity?

Material and finish selection influence cost beyond their initial price tag. The decision creates a multiplier effect impacting machining time, tool life, and long-term value.

1. The Machinability Factor in Budgeting for Custom Parts

The machinability of a material—how easily it can be cut—directly affects cycle times and tool consumption. While a material like titanium offers high strength, its poor machinability compared to aluminum leads to longer cycles and higher costs. Budgeting for custom parts must account for these operational expenses, not just the raw material cost per kilogram.

2. Strategic Surface Finish Selection

Surface finishes are not created equal. Sometimes, a more durable and slightly more expensive finish can be more economical by eliminating the need for secondary processing or providing longer service life. Aligning finish specifications with the part’s actual application prevents over-engineering and unnecessary expense, which is crucial for optimizing production value.

3. Linking Material Efficiency to Sustainability

Optimizing material use is not just a cost-saving tactic; it’s a core tenet of sustainable manufacturing. Minimizing waste aligns with the smart manufacturing practices outlined by National Institute of Standards and Technology (NIST), which emphasize resource efficiency as a driver of both economic and environmental performance.

What Role Does Sustainability Play in Modern Cost-Efficient Manufacturing?

Far from being a mere compliance cost, modern sustainable manufacturing practices are direct contributors to operational excellence and cost efficiency.

- Energy and Resource Efficiency as a Cost Driver: Optimizing tool paths for minimal air-cutting time, implementing high-efficiency cooling systems, and recycling metal scrap are practices that directly lower energy and material consumption. These initiatives, often part of an ISO 14001 Environmental Management System, reduce overhead and lower the carbon footprint simultaneously.

- Lean Principles for Operational Excellence: Adopting lean manufacturing principles to eliminate waste—such as unnecessary motion, waiting, and over-processing—shortens lead times and reduces operational overhead. This focus on continuous flow and efficiency is a hallmark of industrial technology trends aimed at maximizing value.

- The Economic Value of Green Credentials: A demonstrated commitment to sustainability is increasingly a prerequisite for securing contracts from large corporations and institutions with strong ESG (Environmental, Social, and Governance) mandates. This market access provides a tangible economic return on sustainable investments, making the choice of an environmentally certified partner a sound long-term decision.

How Do Certifications Like IATF 16949 and AS9100D Impact Part Quality and Total Cost?

Advanced industry certifications are proxies for reliability and risk mitigation. They signify a culture of precision and continuous improvement that prevents defects and controls the total cost of ownership.

1. Preventing Defects to Avoid Downstream Costs

Certifications like IATF 16949 (automotive) and AS9100D (aerospace) mandate rigorous process controls, advanced quality planning, and full traceability. This systematic approach ensures high first-pass yield, preventing expensive rework, production delays, and catastrophic field failures that dwarf any initial unit price savings.

2. Ensuring Compliance and Market Access

For regulated industries, these certifications are non-negotiable. They demonstrate a supplier’s capability to meet stringent industry-specific requirements, ensuring parts are compliant and safe. This is indispensable for precision engineering insights in sectors like medical devices, where ISO 13485 certification is critical.

3. Building a Foundation for Long-Term Partnership

The disciplined quality culture fostered by these certifications builds a foundation of trust. It assures customers of consistent performance and a shared commitment to excellence, making the certified partner an integral part of their supply chain risk management strategy.

When Should You Partner with a Specialist for Complex Part Fabrication?

When a project involves high complexity, stringent quality requirements, and cost sensitivity, partnering with a specialist becomes not an option, but a necessity for success.

1. Evaluating Technical Capabilities and Expertise

An ideal partner offers more than just 5-axis machines. They possess deep expertise in complex part fabrication, provide proactive DFM support, and hold a comprehensive suite of certifications relevant to your industry. This combination of technology and knowledge is essential for navigating challenging projects.

2. The Importance of End-to-End Collaboration

True cost optimization is achieved through a seamless, collaborative relationship from concept to production. A partner invested in your success will work as an extension of your team, ensuring learning is transferred and value is maximized at every stage.

3. Making an Informed Partnership Decision

Selecting the right manufacturing partner is the ultimate strategic lever. For high-stakes projects, a thorough evaluation of a supplier’s 5-axis CNC machining services is the critical first step toward establishing a partnership that delivers lasting competitive advantage.

Collaboration Framework for Maximum Impact:

| Collaboration Phase | Core Action | Expected Benefit |

| Concept Design | Early DFM consultation with supplier engineers | Avoid fundamental design flaws, lock in majority of cost savings |

| Detailed Design | Joint Critical Function Analysis & tolerance optimization | Achieve significant cost savings while ensuring performance |

| Prototype Validation | Form, fit, and function testing using rapid prototyping | Reduce financial and technical risks in mass production phase |

| Production & Quality | Leverage supplier’s comprehensive quality assurance (e.g., CMM inspection) | Ensure parts consistently meet specifications, avoid downstream costs |

| Continuous Improvement | Feedback production data for future design iterations | Build a lasting competitive advantage and cost-effectiveness |

Table 1: illustrates key collaborative phases between manufacturers and suppliers in the product development process, aiming to optimize cost and quality through early intervention and continuous improvement.

Conclusion

Optimizing 5-axis CNC machining cost is a strategic, multi-faceted endeavor that extends far beyond price comparison. By systematically applying the five levers of precise quoting, design optimization, intelligent material selection, sustainable practices, and rigorous quality certifications, manufacturers can transform an advanced manufacturing technique into a source of durable competitive advantage. True cost control is achieved through intelligent, full-process optimization, enabling businesses to unlock savings of up to 25% while enhancing quality and driving innovation.

FAQs

Q1: What is the biggest misconception about 5-axis CNC machining costs?

A: The biggest misconception is that the machine’s hourly rate is the primary cost driver. In reality, the part’s design complexity is far more impactful. A poorly designed part requiring multiple setups on a 3-axis machine can ultimately be more expensive than a well-optimized design manufactured efficiently on a 5-axis machine.

Q2: How does 5-axis machining actually save money compared to 3-axis for complex parts?

A: 5-axis machining saves money through reduced setup time and improved accuracy. A complex part that would require multiple manual rotations and re-fixturing on a 3-axis machine can often be completed in a single setup on a 5-axis machine. This eliminates cumulative errors, reduces labor, and slashes the risk of scrap.

Q3: Can you provide a realistic example of how design changes reduce cost?

A: Absolutely. Consider a part with a deep, threaded hole on a slanted surface. A traditional design might require a costly custom fixture. A 5-axis-friendly redesign would adjust the angle so the machine’s rotating head can approach it directly, eliminating the fixture cost and setup time. Another example is consolidating multiple components into a single, monolithic part, saving on assembly.

Q4: Why should I care about a manufacturer’s certifications like IATF 16949 for my project?

A: Certifications are a proxy for reliability and risk mitigation. A certified manufacturer is far less likely to deliver defective parts that cause production line stoppages—events whose costs dwarf any minor savings from a non-certified supplier. It ensures consistency and protects your brand reputation.

Q5: How do I get an accurate quote for a 5-axis CNC machining project?

A: To receive the most accurate quote, provide a comprehensive package including a detailed 3D CAD model (e.g., STEP file), 2D drawings with critical tolerances, material specifications, desired surface finishes, and the required quantity. The more information provided, the better the manufacturer can perform a DFM analysis.

Author Biography

The insights in this article are contributed by a senior manufacturing engineering specialist at LS Manufacturing. The company supports innovators in aerospace, medical technology, and robotics by overcoming complex precision part production challenges. As an enterprise holding ISO 9001:2015, IATF 16949, AS9100D, and ISO 14001 certifications, it ensures the highest standards of quality, consistency, and sustainable manufacturing practices. To begin optimizing your next project, Contact their team to obtain a customized 5-axis machining quote optimized for your specific design.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.