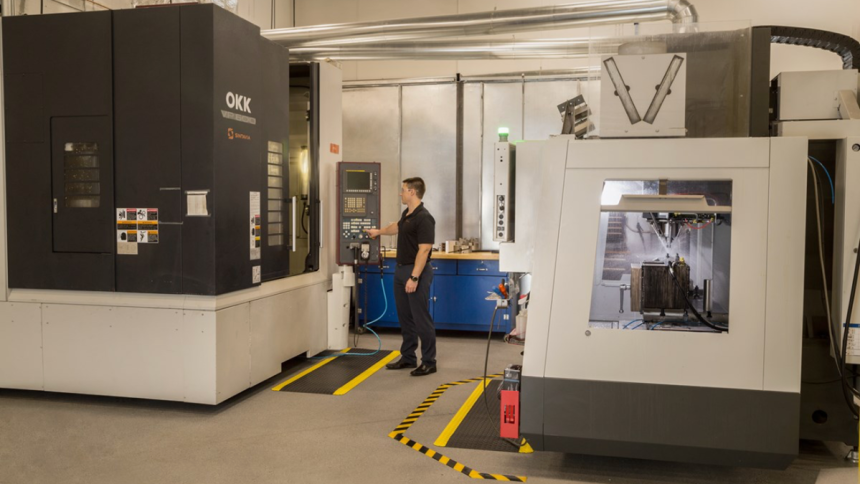

A production line where advanced systems not only track machinery output but also notice when a worker’s posture shifts from focus to fatigue. In many industries, technology is still viewed primarily as a way to boost speed and precision. But as work demands intensify and personal well-being comes under strain, there is a growing case for using the same tools to protect health.

The conversation around technology and employee well-being is no longer about “whether” the two can coexist, but “how” they can actively support each other. This isn’t a futuristic vision, it’s a change already in motion. The challenge now is making that shift intentional.

The Hidden Cost of Efficiency

Many workplaces have embraced a culture that values constant monitoring and output. While the data may help optimize production, it often overlooks the human experience behind the numbers. Workers may meet every target while quietly dealing with fatigue, stress, or injury.

Part of the problem is that well-being measures are treated as separate from core operations. When support systems are reactive rather than proactive, employees fall through the gaps. Some organizations are addressing this by integrating resources such as employee health and benefits programs directly into workplace platforms. By making assistance accessible at the first sign of strain, rather than after a crisis, technology becomes a safeguard instead of a pressure point.

This shift requires more than policy updates; it demands a re-evaluation of what success looks like. Instead of measuring only throughput, companies can also track indicators of sustained performance and workplace satisfaction.

Moving From Oversight to Support

The traditional model of workplace technology has been one of oversight: strict schedules, output logs, and alerts when someone falls behind. A modern approach turns those same capabilities toward support. Wearables can detect signs of overexertion. Smart scheduling systems can recommend short breaks when fatigue risk is high.

Implementing even a small pilot program can reveal how much of a difference this makes. Imagine a single production cell using sensors to track environmental conditions and employee strain, then suggesting quick interventions, stretch breaks, hydration reminders, or ergonomic adjustments. The result is not only improved morale but also reduced downtime from preventable issues.

When technology actively maintains employee capacity, innovation and productivity grow together.

Innovation and Responsibility in Manufacturing

In advanced production, additive manufacturing has become a symbol of flexibility and precision. Yet the process introduces unique challenges for employee health: exposure to fine powders, chemical compounds, and repetitive tasks can create both immediate and long-term strain. Forward-thinking companies are addressing these risks by integrating safety measures and monitoring systems directly into the workflow. For example, real-time sensors can track air quality and worker posture, while automated handling reduces physical strain.

By embedding safety and well-being into the design and operation of additive manufacturing processes, companies demonstrate that innovation and employee care are complementary, not competing, goals. The technology itself becomes a tool not only for efficiency but also for safeguarding the people who operate it.

The Real Measure of Progress

Modern industry cannot define success solely by output. Sustainable progress happens when technology and employee well-being reinforce each other. Machines can make production faster, but the workforce’s resilience determines whether that success lasts.

The question for leaders is simple: does your workplace technology monitor only performance, or does it protect the people delivering it?

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.