Freight security continues to evolve alongside digital tracking and supply chain automation. However, physical indicators remain one of the most trusted methods for detecting tampering and ensuring shipment integrity. From roadside transfers to final-mile deliveries, visual cues help validate whether goods have remained secure throughout their journey. Even with modern sensors and alerts, many carriers still rely on physical tools to reinforce accountability. Simplicity and visibility often make the difference in fast-paced logistics operations. When confirmation is needed quickly, physical evidence provides instant clarity.

This clarity becomes especially important in high-volume distribution environments where speed and accuracy go hand in hand. Physical seals and tapes offer more than deterrence; they communicate control. Operators and inspectors can immediately flag anomalies without opening containers or interrupting flow. This minimizes downtime while keeping protocols intact across each handoff. As risks become more sophisticated, so must the tools used to prevent them. These tools form the first layer of defense in a modern security strategy.

Visibility That Drives Confidence

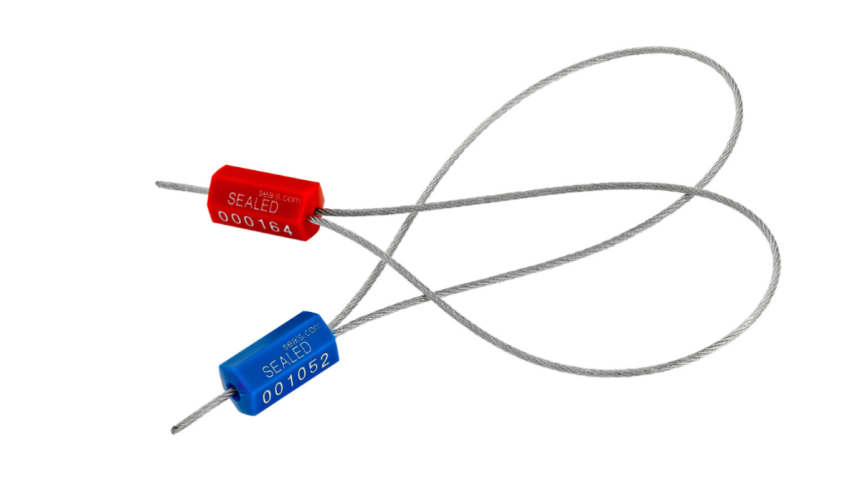

Freight security thrives on fast, confident decision-making. Tools like cable seals offer a clear visual indicator of whether access was attempted. These simple mechanisms make it easy for personnel to identify potential breaches without additional equipment. Their tamper-resistant design helps minimize the risk of accidental breakage, making them ideal for repeated handling. In large hubs where efficiency matters, these quick visual checks make a significant operational impact. Furthermore, they offer a consistent baseline for security across varying routes and vendors. This reliability supports broader chain-of-custody initiatives without adding complexity.

Beyond the hardware itself, the protocols surrounding these tools reinforce trust. Seals are often logged, cross-checked, and verified at multiple checkpoints. These steps create a paper trail that supports audits and investigations if tampering is suspected. Not only do they signal that access has occurred, but they also validate who interacted with the cargo and when. Even when technology fails, these visible elements provide continuity. They remain relevant because they’re dependable in unpredictable environments. This dependability is what keeps them essential in freight workflows.

Layered Tamper Protection Strategies

While seals prevent unauthorized access, visual warnings enhance deterrence. Security tape offers a secondary layer that works hand in hand with other tools. It adheres to packaging surfaces and reveals messages or distortions when removed or tampered with. This makes it an effective option for cases, cartons, and lightweight cargo where heavier locks aren’t practical. These markings alert handlers and recipients before the goods are even opened. The visibility is immediate, helping prevent false claims and disputes over delivery conditions. This protection adds value at every step, from warehouse to receiver.

The tape itself can be tailored to meet environmental or operational needs. Some tapes resist moisture or extreme temperatures, while others work best in standard shipping conditions. When paired with proper training, handlers learn to recognize when tampering has occurred just by glancing at the seal. This shortens investigation time and ensures damaged goods are flagged early. In supply chains that span multiple stops and carriers, that early detection becomes critical. The tape’s clear signals empower workers across roles to respond with certainty. That certainty streamlines the entire chain of accountability.

Seals That Withstand Mobile Conditions

Transport environments often involve motion, vibration, and unpredictable contact points. Trailer seals are engineered to remain intact under these changing conditions. These seals protect the rear doors, side entries, and compartments that are frequently accessed during transit. That visual indicator supports faster checks at checkpoints and receiving docks. Because trailers may pass through multiple handlers, consistent sealing practices help reinforce trust. When properly applied, these seals show whether any attempt to open the trailer occurred between stops. That assurance becomes essential for time-sensitive or regulated cargo.

More importantly, trailer-based sealing systems must balance strength with usability. They need to resist unauthorized removal while still allowing for easy verification by authorized teams. Seals that are too complex delay operations, while those that are too simple can be bypassed easily. As companies aim for faster delivery timelines, these details grow in importance. Reliable trailer sealing improves handoff efficiency without sacrificing protection. Each trailer door becomes a checkpoint of its own, helping keep security protocols consistent across geographies. This consistency anchors broader efforts in supply chain visibility.

Auditing Support Through Physical Indicators

Accurate audits require more than just data; they rely on observable, time-stamped points of control. Physical tools like seals and tape act as evidence that standard procedures were followed during transit. When an issue arises, these tools become part of the forensic process used to determine what went wrong and where. Teams reviewing shipping discrepancies depend on clear tamper indicators to verify or dismiss claims. These indicators help distinguish damage that occurred in transit from issues at the receiving dock. This leads to a more efficient investigation process and stronger accountability across the chain.

This type of visual documentation supports internal quality control and external compliance efforts. When regulatory audits occur, having consistent seal protocols and documented practices helps organizations demonstrate due diligence. Inspectors often look for a pattern of reliability, and visible seals offer tangible proof that protocols were enforced. Furthermore, using standardized seal identifiers can help align with global compliance requirements. This allows companies operating across borders to maintain trust with partners and authorities. Over time, it positions physical security tools as essential components of a risk management framework.

Wrap Up

Security in freight movement depends on clarity, consistency, and control. While digital systems offer real-time updates and analytics, physical tools provide immediate verification that technology alone cannot guarantee. Visual indicators like seals and tapes simplify inspections and strengthen every stage of cargo handling. Each checkpoint becomes an opportunity to validate security measures without introducing delay. As regulations grow stricter and customer expectations rise, the margin for error narrows quickly. Smart integration of visual tools helps close that gap and reinforce organizational credibility. It’s not just about deterrence but about maintaining accountability across every touchpoint.

Ultimately, physical security measures continue to evolve alongside digital systems. The freight industry relies on a layered approach where visibility and simplicity remain essential over added complexity. When implemented properly, these tools turn each shipment into a clear statement of intent that it is safe, secure, and carefully managed. Operations cannot afford to stall due to uncertainty, and seals provide the quick verification needed to maintain momentum. In a global system full of unpredictable elements, visible proof of protection still carries significant value. Freight security continues to rely on the clarity that only physical evidence can consistently deliver.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.