Imagine driving your car everywhere with only two options: the accelerator pressed fully to the floor, or the engine completely off. It sounds incredibly wasteful, right?

This is exactly how many industrial motors have traditionally operated. Whether powering pumps, fans, or conveyors, these motors often run at full speed constantly, regardless of actual demand. The result? Enormous amounts of wasted energy and inflated operating costs.

Fortunately, there’s a smarter way. Variable Frequency Drives (VFDs) act like a precision accelerator for electric motors, adjusting motor speed to match real-time demand. This article explores what VFDs are, how they dramatically reduce energy consumption, and the broader operational benefits they bring.

What is a Variable Frequency Drive (VFD)?

At its core, a Variable Frequency Drive is an electronic device that controls the speed of an AC electric motor by adjusting the frequency of the electrical power supplied to it.

To visualize this, think of a VFD as a sophisticated dimmer switch—not for lights, but for motors. Instead of toggling the motor fully on or off, it provides a full spectrum of speed control. This enables motors to operate precisely as needed, conserving energy and reducing mechanical stress.

A VFD consists of three essential components:

- Rectifier: Converts incoming AC (alternating current) power into DC (direct current).

- DC Bus: Temporarily stores the electrical energy.

- Inverter: Converts the stored DC back into AC, but at a controlled frequency and voltage suitable for the desired motor speed.

This sequence enables seamless modulation of motor speed and torque in response to operational requirements.

The Physics of Savings: The Affinity Laws Made Simple

Let’s consider a typical scenario: a ventilation fan in a commercial building. Without a VFD, the fan runs at full speed even if only half the airflow is needed. Excess air is mechanically throttled—like flooring your car’s accelerator while applying the brake to control speed. It’s inefficient and unnecessary.

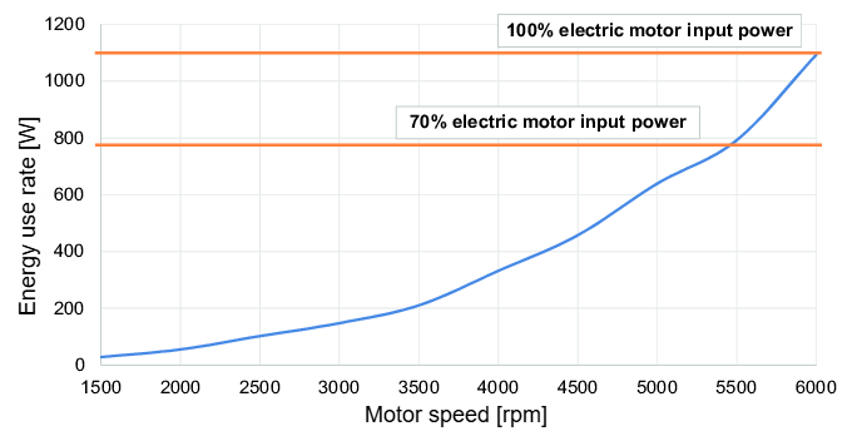

Here’s where the Affinity Laws come in. While rooted in physics, the principle is straightforward: for pumps and fans, a small reduction in motor speed leads to a disproportionately large reduction in energy consumption.

For example, reducing a fan’s speed by just 20% can lower its energy usage by nearly 50%. This non-linear relationship between speed and power is a key reason VFDs are so effective in cutting energy waste.

By allowing motors to run only as fast as needed, VFDs unlock substantial energy savings with minimal performance trade-offs.

VFDs in the Real World: Applications & Impact

The value of VFDs becomes even clearer when we examine real-world use cases:

- HVAC Systems in Commercial Buildings: VFDs adjust fan speeds in response to occupancy levels or external temperatures. This real-time responsiveness translates into major reductions in electricity bills and carbon footprint.

- Industrial Pumping Systems: Instead of cycling on and off at full power, pumps equipped with VFDs maintain consistent water pressure by adjusting motor speed. This minimizes wear and reduces system instability.

- Conveyor Belts in Manufacturing: VFDs facilitate smooth start-ups and allow speed changes to align with production requirements. This reduces mechanical shock, product damage, and system downtime.

For those evaluating options, selecting the right drive depends on motor specifications and application needs. Explore available solutions on https://www.chipsgate.com/collections/plc.

Beyond Energy Bills: The “Hidden” ROI of VFDs

While energy savings are often the headline benefit, VFDs deliver additional returns that make them a compelling investment for operations and IT managers alike:

- Reduced Mechanical Wear and Tear: Traditional motor start-ups create mechanical shock, stressing belts, gears, and the motor itself. VFDs enable “soft starting,” significantly extending equipment lifespan and lowering maintenance demands.

- Improved Process Control: With precise speed adjustments, VFDs enhance product quality and consistency. In production lines, this can mean fewer defects, less waste, and smoother operations.

- Actionable Operational Data: Many modern VFDs are equipped with smart features, providing data on energy consumption, motor health, and faults. This data supports predictive maintenance strategies and integrates with broader IT systems for operational transparency.

In all these applications, the quality of the drive and its components is crucial to achieving these outcomes. That’s why many professionals rely on ChipsGate’s industrial components to ensure performance and reliability.

Smarter Control for a Sustainable Future

Running motors at full speed, regardless of demand, is a silent yet significant source of industrial energy waste. VFDs offer a practical, proven solution: they tailor motor performance to actual operational needs.

The benefits are clear:

- Substantial reductions in energy consumption and operating costs

- Extended equipment life due to gentler starts and optimized performance

- Enhanced process control and system efficiency

For many facilities, the return on investment from VFD implementation can be realized in under two years. But more importantly, VFDs represent a strategic step toward smarter, more sustainable operations.

As the industrial sector embraces efficiency and intelligence, VFDs stand out as a foundational technology—delivering not just cost savings, but long-term operational resilience.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.