Safety goes beyond a set of rules; it is something you think about daily.

Imagine all the people working on a construction site feeling secure enough to point out any dangers they notice. Safety isn’t just about ticking boxes or filling papers—it’s a shared value. How a leader behaves influences the team and each person can contribute to the safety. Sounds ideal? It really exists. This is an example of a safety-first culture.

In construction, the stakes are high. Even one mistake may result in the loss of a life. According to the U.S. Bureau of Labor Statistics, nearly one out of five workplace deaths happened in the construction sector in 2022. In most instances, falls, objects falling on them, electric shocks, and getting caught in machinery led to these injuries.

But, what can we do to stop accidents from happening in the first place? Here are five tips to build a safety-first culture as the foundation of every construction project.

Why Safety-First Culture Is Essential for Construction?

Promoting a safe work environment helps people and projects in many ways—far beyond just following the rules. Here is why this is important:

- Reduce Injuries: Solving the fatal four risks – falls, strikes, electrocutions, and caught-in – can save lives and help prevent terrible injuries.

- Enhances Productivity: Safety at construction sites improves workflow, reduces workers’ absences, and maintains projects running on time.

- A bigger reputation: Companies that focus on safety often get the best people, win more tenders and please their customers.

- It Makes Insurance Cheaper: Less collisions and claims decrease what you have to pay for insurance.

- Increases Engagement: Workplace safety at construction sites boosts workers’ engagement and satisfaction.

- Improves Compliance: Meeting OSHA standards becomes easier, reducing legal risks and penalties.

Put simply, safety is not only smart—it’s strategic, humane, and future-ready.

1. Leadership: Set the Tone from the Top

A true safety culture starts at the top. Leaders who walk the talk show everyone that safety is serious. It’s not just about rules—it’s about presence and priority.

Many leading firms use scorecards and incentives to track safety goals. When leaders give safety the same attention as timelines and budgets, the message is clear: people come first.

Example: Turner Construction leads the way with their “Building L.I.F.E.” program, making safety part of every decision from the top down. Executives do site walks, talk with frontline teams, and publicly share progress using real-time safety data.

2. Empowering Through Education

Ongoing education is key to keeping teams alert and ready. Frequent training sessions, toolbox talks, and safety briefings before each shift help everyone stay focused.

But safety isn’t just about knowing rules, it’s about speaking up. Workers should feel empowered to report hazards without hesitation. Spot an exposed wire or an unsupported edge? Say something and fix it before it leads to injury.

Why it matters: Knowledge gives workers the confidence to act. This leads to fewer accidents and stronger ownership of safety practices.

Get started: At Skanska USA, every worker completes an Osha 10 hour course before stepping onto a site. They host daily huddles, weekly safety reviews, and hands-on practice for risky tasks. Their “Injury-Free Environment” initiative empowers everyone to stop unsafe work without fear.

3. Building Trust: Make Communication Safe

Being communicative and truthful is what makes a site secure. Employees should be able to raise their voices about the issues without worrying about the consequences. This is how we can avoid hazards from becoming dangerous.

An easy answer? Create a ‘Safety Suggestion Box’, so that workers can share their concerns without revealing their identities. Finding out where there were difficulties can lead to new changes in signs and PPE at workplaces.

Example: DPR Construction is known for its “Speak Up Culture”. They’ve built psychological safety into their workflow, encouraging all employees to report hazards and near-misses. Their anonymous safety app and feedback system have led to real improvements, like better lighting and added guardrails.

4. Prepare for Emergencies: Train For the Worst

Despite having the best systems, emergencies can arise. This is why learning BLS is important for your team members. Properly trained employees have the ability to use CPR and an AED and save someone’s life in emergency situations.

Why it matters: In case of an emergency, responding faster can save lives. BLS-certified team members are often the first and most vital responders on-site.

Get certified: Construction companies equip key personnel with BLS certification and First Aid skills. They partner with local emergency responders to provide on-site certification, ensuring that teams are ready to step in when seconds matter.

5. Continuous Improvement: Keep Learning, Keep Auditing

Safety isn’t one-and-done. It requires constant attention and evolution. Monthly workshops, safety drills, and regular audits help keep teams sharp and identify blind spots before they become incidents.

Try rotating topics—like ladder safety one month, and hazard communication the next. These hands-on refreshers keep the knowledge fresh and relevant.

Routine audits can uncover unsafe habits or gaps in your safety plan. Treat them as opportunities to grow, not just checklists.

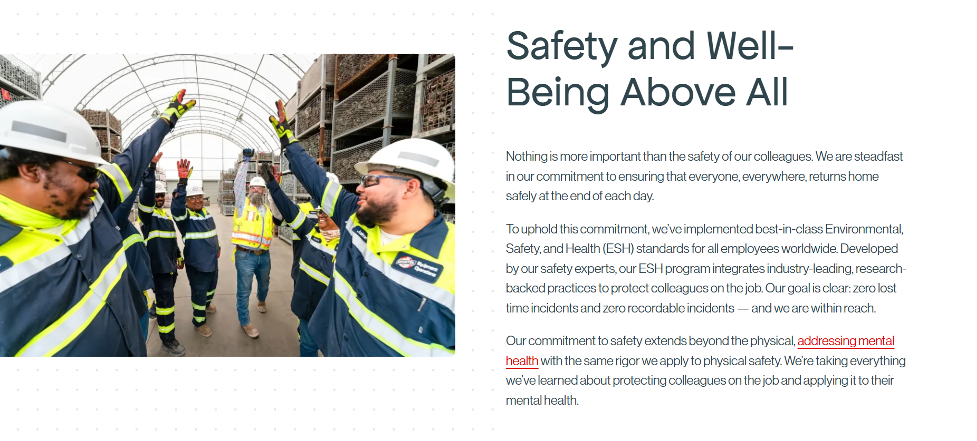

Example: Bechtel runs a global Environmental, Safety & Health (ES&H) audit program, conducting peer reviews and behavior-based observations. Their “Zero Incident Performance (ZIP)” initiative includes monthly training on high-risk areas like fall protection and confined space entry, ensuring lessons are never forgotten.

6. Safety by Design: Start Before You Build

Ensuring safety begins before any workers actually show up to work. Taking safety into consideration in the planning phase can keep potential risks down. This means planning for things like safe access points, fall protection anchors, and using prefabricated parts to avoid dangerous tasks.

Engaging with safety specialists early on helps to recognize safety problems in advance. Smart construction allows for improved project performance and safer results for all workers.

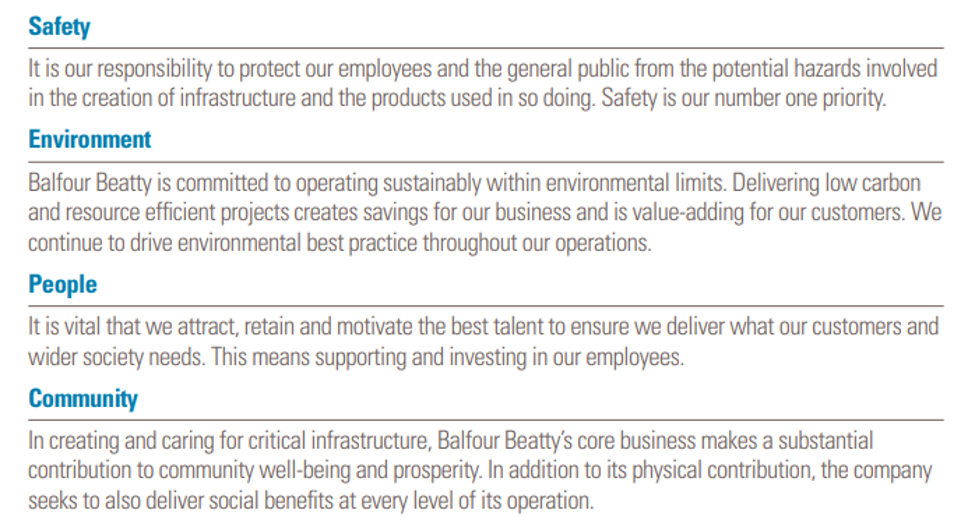

Example: Balfour Beatty’s “Design for Safety” initiative is laid out in its corporate safety strategy reports and its sustainability communications. Their safety experts help in planning early stages using simulation and assessing known risks to avoid construction hazards.

Conclusion: Practice Safety Every Day

A safety-first approach in construction sites goes further than the regulations and law. It aims to ensure everyone’s safety, value their well-being, and create places where everyone feels safe to be.

If you set an example, teach others, encourage them to speak up, plan for any risks, and focus on getting better—then your sites will be more than secure. You create a culture of care.

Because at the end of the day, a safe site isn’t just more efficient—it’s proof that you value what truly matters: human life.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.