AI is not a new concept, but the current AI boom is in its infancy. More and more data centers are coming up to host the servers that run the different AI models, and these need power. Projections show the US data center energy consumption figures will rise from 147 TWh in 2023 to 606 TWh in 2030. This will represent an 11.7% share of the total US power demand (an increase from 3.7%). By 2050, the global data center energy demand could go up to 4,500 TWh.

Renewable energy sources like wind and solar are unreliable and expensive to set up. So the most economically viable solution to get this power available quickly to data centers is investing in thermal energy sources, such as coal and natural gas.

The Problem

While cheap, thermal energy sources have negative effects on the environment. Coal produces the highest levels of pollution in this category, but the US is investing more in natural gas plants, which is good. But these plants also produce low quantities of nitrogen oxides, which forms smog, as well as tiny amounts of particulates, mercury, and sulfur.

Globally, coal power plants accounted for around 34% of the world’s electricity production in 2020. Coal is the dirtiest hydrocarbon fuel because it produces high levels of carbon dioxide, nitrogen oxides, particulate matter, sulfur dioxide, and heavy metals, such as mercury. Combined, these pollutants severely harm the environment and human health.

A coal-fired thermal power plant (Mutiara, India)

The Solution

For natural gas plants, baghouses are essential and often part of the regulatory requirements for emissions control. Also known as bag or fabric filters, baghouses contain multiple filter bags that trap particulate matter from the exhaust gases before exiting to the surrounding air.

But these filters don’t trap nitrogen oxides. Since natural gas plants produce low levels of nitrogen oxides, it is not considered a regulatory requirement to trap the gas. But with the increasing investment in gas-fired power plants, the combined flue gases from them can present health and environmental issues due to the high levels of nitrogen oxides being released into the air.

Coal plants, on the other hand, are required to have electrostatic precipitators (ESPs) to filter out the particulate matter. ESPs are more efficient than baghouses because they trap up to 99% of particulate matter without impeding flue gas flow. Additionally, ESPs are often deployed with scrubbers to remove sulfur dioxide and denitrification units (SCR, SNCR, activated carbon, or oxidation systems) to remove nitrogen oxides.

The Business Opportunity

ESPs with denitrification units and scrubbers are the best solutions to deal with AI’s power-hungry air pollution problem. This solution is also important for other industries that emit harmful gases, not only thermal power plants.

The global ESP market was valued at $9.1 billion in 2024 and is expected to grow at 6% (CAGR) from 2025 to 2034 (eventually hitting a valuation of $16.7 billion). This growth will be driven by increasing industrialization, which includes data center investments, in emerging economies and the thermal power production needed to power these industries. More stringent environmental regulations will demand cleaner flue gas emissions, meaning ESPs will be critical to meeting the required air quality standards.

Denitrification and scrubbing are generally simple processes because they involve injecting a reductant or absorbent material to react with the harmful gases/contaminants or absorb them. The challenging part is building the ESP.

How Electrostatic Precipitators Work

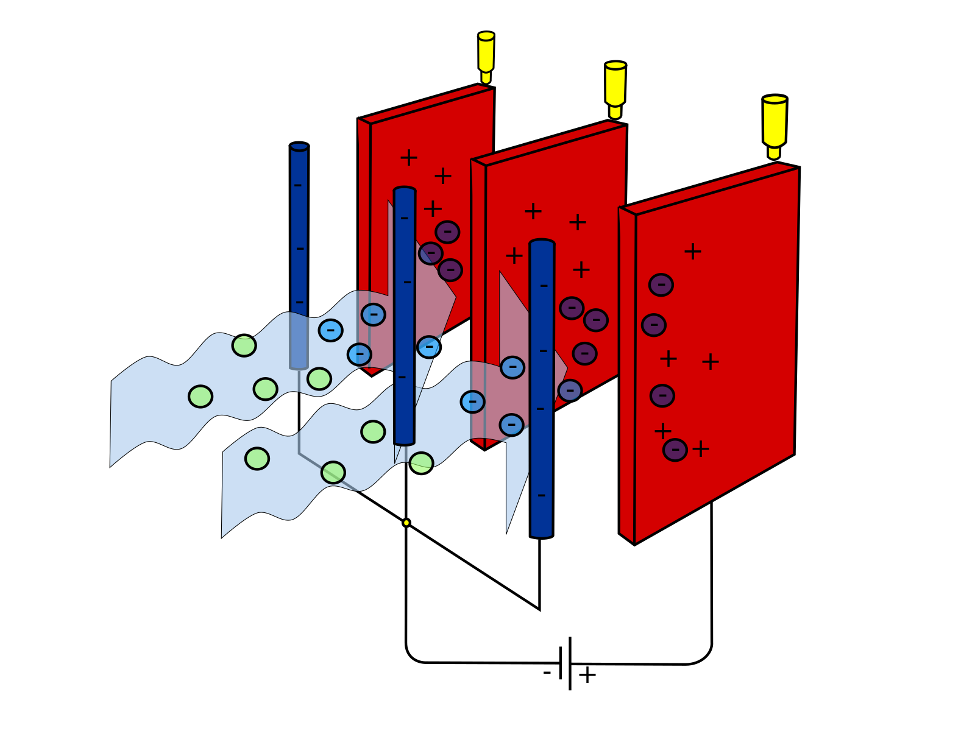

As the name suggests, ESPs operate using the principle of electric current charge/static attraction. The most common type (plate and bar) features rows of thin vertical wires placed in front of a stack of broad, flat metal plates that are evenly spaced out. But the ESP design can also be tubular. As the flue gas flows through the ESP, it passes through the wires first, then through the plates.

A plate and bar ESP’s operating principle

A high negative voltage is applied between the wires and the plates during operation. This creates a corona discharge that ionizes the particles in the air stream. As this air approaches the plates, the ionized particles get attracted to the positively charged plates. These particles accumulate on the plates and are removed periodically via vibration or rapping.

A tubular ESP

Structurally, this device has four major parts:

- Power supply unit to provide the high-voltage direct current

- Ionizing section consisting of wires and plates (or tubes)

- Mechanism for particulate collection

- Housing structure

There are also the high-voltage wire harnesses needed to connect the power supply unit to the ionizing section.

How To Stay Ahead of the Competition

If you’re in the air purification or filtration business, one way to stay ahead of the competition while also increasing ESP adoption in the thermal power generation industry is to build cheaper systems. This is only possible if you can access low-cost parts from credible and reputable suppliers.

Wiringo specializes in the manufacturing and assembly of different cable types, including high-voltage and special-purpose varieties, which you can use to make ESP machines. This cable harness manufacturer can also custom-make wire harnesses to OEM specifications, meaning all your wiring needs can be met by one supplier at low costs. Reach out to them for more information or to request a free quote for your order.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.