In the rapidly evolving landscape of modern manufacturing, the journey from a conceptual design to a tangible product has been significantly transformed by technological advancements. Among these, laser machines have emerged as pivotal tools in advanced product development, bridging the gap between imagination and reality with unparalleled precision and efficiency. This article delves into the integration of laser machines in product development, exploring their roles, benefits, and the transformative impact they have on various industries.

1. The Evolution of Product Development

Traditionally, product development involved a linear process: idea generation, sketching, prototyping, testing, and finally, mass production. This method, while effective, was often time-consuming and limited by the precision and capabilities of conventional manufacturing tools. The advent of laser technology has revolutionized this process, introducing new possibilities for design complexity, material versatility, and production speed.

2. The Role of Laser Machines in the Design Phase

Computer-Aided Design (CAD) Integration

The journey from design to reality begins with Computer-Aided Design (CAD) software, where designers create detailed 2D or 3D models of their products. Laser machines seamlessly integrate with CAD platforms, allowing for direct translation of digital designs into physical forms. This integration ensures that designs are executed with high fidelity, maintaining the integrity of intricate details that might be challenging to achieve with traditional tools.

Precision and Accuracy

Laser machines boast exceptional precision, often within microns, enabling designers to explore complex geometries and fine details without compromising on accuracy. This level of precision is particularly beneficial in industries such as aerospace, automotive, and electronics, where even minor deviations can significantly impact performance and safety.

3. Prototyping: Rapid and Iterative Development

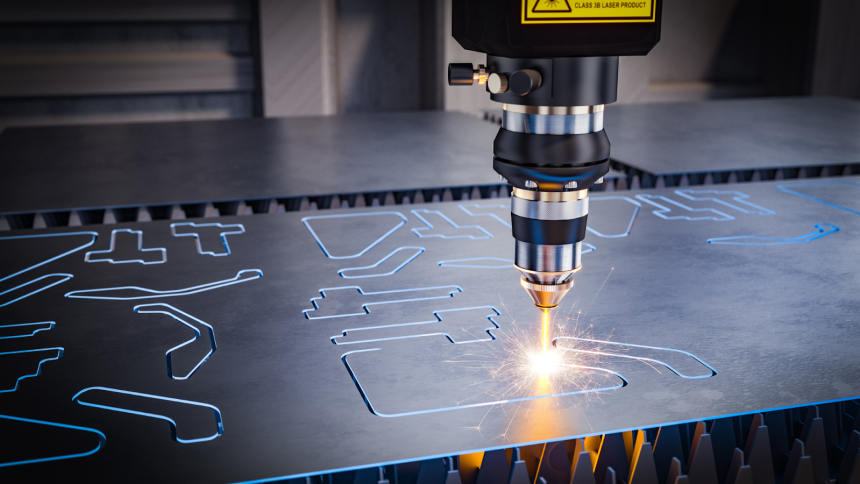

One of the most significant contributions of laser machines to product development is their ability to facilitate rapid prototyping. Laser cutting and engraving allow for quick production of prototype parts from various materials, including metals, plastics, and composites. This rapid turnaround enables designers to iterate swiftly, testing and refining their concepts without the delays associated with traditional prototyping methods.

4. Manufacturing: From Single Units to Mass Production

Laser Cutting and Engraving

In the manufacturing phase, laser cutting offers unparalleled accuracy and speed in processing materials. Whether it’s fabricating intricate parts for machinery or customizing consumer products, laser cutters ensure clean, precise edges and consistent quality across large production volumes. Additionally, laser engraving enables the addition of detailed markings, logos, or textures without compromising the material’s integrity.

Laser Welding and Joining

Laser welding has become a cornerstone in modern manufacturing, providing strong, seamless joins in various materials. Unlike traditional welding, laser welding minimizes heat distortion and welding time, enhancing the overall structural integrity of the product. This is particularly advantageous in industries requiring high-strength connections, such as automotive and electronics.

Flexible Manufacturing Systems

The adaptability of laser machines allows manufacturers to switch between different tasks with minimal downtime. This flexibility is crucial in industries where customization and short production runs are prevalent. Laser systems can be reprogrammed quickly to accommodate new designs, enabling businesses to respond swiftly to market demands and consumer preferences.

5. Quality Control and Precision Enhancement

Consistency and Repeatability

Laser machines excel in maintaining consistent quality across multiple production runs. Their automated nature reduces the risk of human error, ensuring that each product meets the specified standards. This repeatability is essential for maintaining brand reputation and customer satisfaction.

Non-Destructive Testing

Advanced laser systems can be integrated with non-destructive testing (NDT) technologies, such as laser scanning and imaging, to inspect products for defects without damaging them. This integration enhances quality control processes by providing real-time feedback and enabling immediate corrective actions during production.

6. Benefits of Integrating Laser Machines in Product Development

Enhanced Design Capabilities

Laser technology empowers designers to push the boundaries of creativity, allowing for the realization of complex and innovative designs that were previously unattainable. This leads to the creation of unique products that stand out in the market.

Increased Production Efficiency

The speed and automation offered by laser machines significantly reduce production times. Tasks that once took hours can now be completed in minutes, enabling faster time-to-market and increased production capacity.

Cost-Effectiveness

While the initial investment in laser technology may be substantial, the long-term benefits include reduced labor costs, minimized material waste, and lower maintenance expenses. The precision of laser machines also decreases the likelihood of defective products, further driving cost savings.

Material Versatility

Laser machines can process a wide array of materials, from metals and plastics to ceramics and glass. This versatility allows manufacturers to experiment with different materials, enhancing the functionality and aesthetics of their products.

7. Industry Applications and Case Studies

Automotive Industry

In the automotive sector, laser machines are used for manufacturing components such as fuel injectors, dashboard elements, and structural parts. For instance, laser welding ensures robust joins in engine assemblies, enhancing performance and safety.

Aerospace Industry

The aerospace industry leverages laser technology for producing lightweight, high-strength components essential for aircraft and spacecraft. Laser cutting allows for precise fabrication of turbine blades and fuselage parts, while laser additive manufacturing creates specialized components with complex geometries.

Consumer Electronics

In consumer electronics, laser machines are integral to producing intricate circuit boards, casings, and display components. The precision of laser cutting and engraving ensures that electronic devices are both functional and aesthetically pleasing.

Medical Devices

Laser technology enables the production of highly accurate medical devices, such as surgical instruments, implants, and diagnostic equipment. The ability to work with biocompatible materials and achieve precise tolerances is critical in the medical field.

Fashion and Footwear

The fashion industry utilizes laser cutting and engraving to create detailed patterns and custom designs in textiles, leather, and other materials. This technology facilitates the production of bespoke garments and accessories, catering to the demand for personalized fashion.

8. Future Trends: The Evolving Role of Laser Machines

Integration with Artificial Intelligence and Machine Learning

The future of laser technology in product development lies in its integration with artificial intelligence (AI) and machine learning. AI can optimize laser parameters in real-time, enhancing precision and reducing errors. Predictive maintenance powered by machine learning algorithms can also improve the reliability and lifespan of laser machines.

Hybrid Manufacturing Systems

Hybrid systems that combine laser technology with other manufacturing processes, such as robotics and additive manufacturing, are set to become more prevalent. These integrated systems offer greater flexibility and efficiency, enabling the production of highly customized and complex products.

Sustainability and Green Manufacturing

Laser machines contribute to sustainable manufacturing practices by minimizing material waste and reducing energy consumption. Future advancements may further enhance the eco-friendliness of laser technology, aligning with the global push towards greener production methods.

Miniaturization and Microfabrication

As technology advances, laser machines are enabling the production of miniaturized components with intricate details. This is particularly significant in sectors like electronics, biotechnology, and nanotechnology, where the demand for smaller, more efficient components is ever-increasing.

9. Challenges and Considerations

High Initial Investment

The cost of acquiring and maintaining laser machines can be a barrier for small and medium-sized enterprises (SMEs). However, the long-term benefits often outweigh the initial expenses, particularly when considering the efficiency and quality improvements.

Skill Requirements

Operating advanced laser machines requires specialized training and expertise. Manufacturers must invest in workforce development to fully leverage the capabilities of laser technology.

Safety Concerns

Laser machines pose specific safety risks, including exposure to intense light and heat. Implementing proper safety protocols and protective measures is essential to ensure a safe working environment.

10. Conclusion

Integrating laser machines into advanced product development represents a significant leap forward in manufacturing capabilities. From enhancing design precision and accelerating prototyping to enabling mass production and ensuring consistent quality, laser technology plays a multifaceted role in transforming ideas into reality. As industries continue to seek innovative solutions to meet evolving market demands, the adoption of laser machines will undoubtedly remain a cornerstone of modern manufacturing processes. Embracing this technology not only fosters creativity and efficiency but also paves the way for sustainable and cutting-edge product development, shaping the future of manufacturing and industry at large.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.