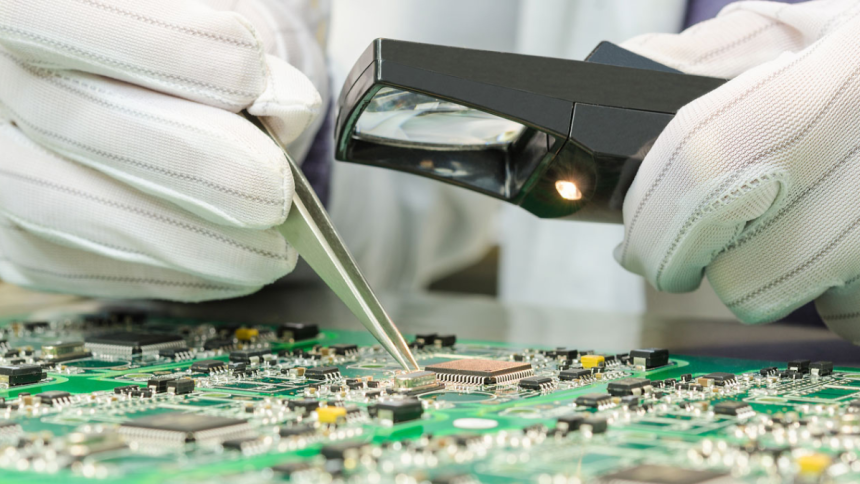

The manufacturing and technology sectors must ensure the quality and reliability of printed circuit boards. Several B2B companies offer various PCB testing services to help them meet stringent performance and safety requirements. With advanced testing methods and tailored solutions at every stage, these providers can help you streamline production, remain compliant with industry standards and boost your bottom line.

Top 4 PCB Testing Service Providers

PCB testing is necessary to ensure your product design is well-built and defect-free. These four testing service providers can assist you with this complex process, protecting your investment and reputation.

1. Via Technology

Via Technology performs comprehensive evaluations of electronic circuit boards to catch flaws and compliance issues. With advanced technologies, the team will deliver unit and system integrations, third-party certification testing, customized fixture and software development testing, and production testing.

The process includes visually inspecting the board for scratches, misalignments and defects. Technicians will then sample its components and connections before issuing isolation testing.

This organization has over 40 years of combined experience and 13 areas of expertise. Additionally, 75% of its business dealings comprise referrals and repeat customers.

Location: West Seneca, New York

Established: 1992

Industries served: Aerospace, military, industrial, commercial, medical and scientific

2. Janco Electronics

Janco Electronics provides advanced PCB testing services, including automated in-circuit, flying probe, and high-potential methods. It also checks assembly performance via functional testing with industry-standard equipment. Additional probes include thermal chamber and burn-in testing to determine environmental vulnerabilities and potential failures.

The company has over 60 years of experience and maintains ISO 12485 certification through the International Standard Organization. Each test is fully documented and traceable to ensure regulatory compliance and consistency. The team also reviews the results and delivers detailed reports for your records. They will then work with you to identify issues and implement solutions.

Location: Rollinsford, New Hampshire

Established: 1958

Industries served: Medical, aerospace, defense, telecommunications, industrial and commercial

3. SunMan Engineering

SunMan Engineering offers tailored solutions for PCB testing, including visual inspection, in-circuit, automated optical inspections, flying probe, X-ray inspection, burn-in and functional. Its rigorous process guarantees your PCB meets quality assurance criteria and optimal performance before it goes into production.

Since 1990, this organization has served over 350 clients and completed over 1,550 projects. Outsourcing PCB testing to a company like SunMan Engineering allows you to focus on developing and improving your product and keeping up with market changes over time.

Location: San Jose, California

Established: 1990

Industries served: Medical technology, robotics and automation, consumer electronics, aerospace and semiconductor services

4. Cascade Systems Technology

Cascade Systems Technology (CST) provides numerous PCB testing methods, from simple to automated checks and finished product validation. CST acts as a partner to your test department, assisting with designing and building systems for thorough analysis.

This business takes a hands-on approach to electronic contract manufacturing, enabling it to resolve issues efficiently and promptly. After you request a quote, you will receive an experienced account manager as a point of contact.

The CST engineering team maintains ISO 9001:2015 certification and complies with ISO 14001, demonstrating a commitment to proper waste management and environmental responsibility.

Location: Hillsboro, Oregon

Established: 1990

Industries served: Computing, military, aerospace, medical, semiconductor manufacturing, clean energy, electric vehicles, industrial controls and Internet of Things applications

How to Choose the Best PCB Testing Services

Choosing the best PCB testing services requires researching an organization’s technical expertise and long-standing reputation. Compliance is especially crucial when partnering with a service provider. Create a chart to compare each company and determine which provides the best PCB testing tools and techniques to meet your needs. Consider the following factors in making a sound decision:

| Technical Capabilities | Specializations in PCB testing methods, including in-circuit, functional, flying probe, automated optical inspection and X-ray inspection |

| Quality Assurance | Quality management procedures and validation frameworks, certifications and traceability solutions |

| Communication and Customer Support | Technical support, communication modes, responsiveness and service documentation |

| Value Proposition | Transparent and competitive pricing with detailed estimated quotes |

| References and Reviews | Customer reviews and testimonials, a positive rating on the Better Business Bureau, and a proven track record of success |

What Are the Most Common PCB Testing Methods Used in Manufacturing Today?

Testing PCB boards is crucial for identifying errors and improving the overall safety and quality at various stages of development. Each testing method has advantages and disadvantages, and it must fit the situation and your budget. Manufacturers often turn to these PCB testing methods:

- In-circuit testing: Evaluates individual components and connections for shorts, opens and other defects with precision

- Flying probe testing: Uses moving probs to test various points and is ideal for low-volume production and prototypes

- Automated optical inspection: Use high-resolution cameras and artificial intelligence to detect defects in PCB assemblies

- X-ray inspection: Delivers noninvasive imaging of internal PCB structures

- Functional testing: Last step for checking the operational functioning of a fully assembled PCB to ensure it works properly in real-world situations

The appropriate PCB testing tool depends on the project requirements, production volume, component types and circuit complexity. For example, an in-circuit test may be a better option for mass production than fly probe testing, which is better suited for low-volume production.

How Can PCB Assembly Testing Help Ensure Compliance With Industry Standards and Regulations?

Assembly testing is critical for compliance with industry benchmarks and regulations. Manufacturers must thoroughly inspect electrical components and functionality to pinpoint defects and avoid faulty products from reaching consumers. The PCB boards must also meet stringent safety and performance standards to prevent hazards and recalls.

PCB functional testing is especially vital in the aerospace, defense and medical device industries. It ensures product reliability and decreases the likelihood of catastrophic failures. This approach streamlines production and reduces manufacturing costs.

Maximizing Value With Expert PCB Testing

The right PCB testing service providers have the knowledge and tools to ensure your product is reliable, compliant and ready for production. Partner with industry experts who deliver an array of testing solutions and support to streamline quality assurance and market penetration.

Lynn Martelli is an editor at Readability. She received her MFA in Creative Writing from Antioch University and has worked as an editor for over 10 years. Lynn has edited a wide variety of books, including fiction, non-fiction, memoirs, and more. In her free time, Lynn enjoys reading, writing, and spending time with her family and friends.